Table of Contents

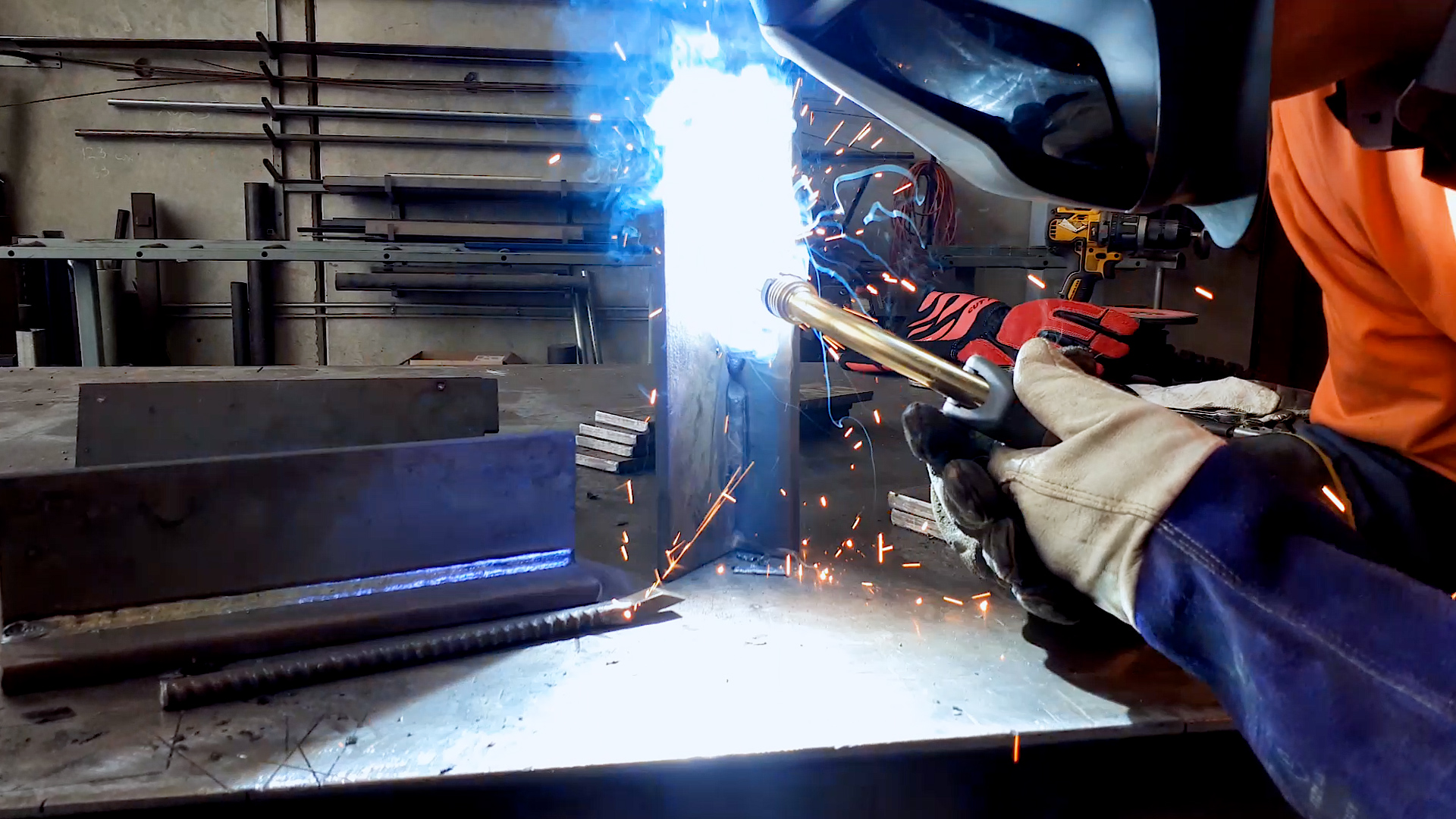

In an industry where precision and efficiency are paramount, Trinder Engineers has taken a significant step forward under Wayne Martin, the company’s welding supervisor. With an extensive background in welding across Australia and New Zealand, Martin has been at the forefront of the company's efforts to innovate and improve welding practices. This commitment is exemplified by integrating the Hyundai SC-420MC wire into their welding processes. This high-quality wire shows Trinder Engineers' dedication to setting industry standards, ensuring that every project benefits from the enhanced quality, reliability, and precision that the Hyundai SC-420MC wire brings to their welding operations.

Solution Exploration: The Search for a Superior Welding Wire

The catalyst for this step was the soaring cost of CO2 gas, a critical component in the welding process. This challenge prompted Chris from Proline Industrial to introduce Trinder Engineers to a revolutionary welding wire that operated on a mix of argon and CO2. Initially, the proposition was met with the usual scepticism accompanying change, especially one driven by cost considerations. Chris from Proline approached us and said, "hey, we've got this wire runs on a mix of argon and CO2... it was more about the cost for the shielding gas because we do use a lot of it." This opened the door to considering the practical benefits of the new wire beyond initial cost-saving implications. The potential benefits of this new wire merited a trial, leading to a series of evaluations to determine its suitability for Trinder Engineers' specific needs.

Trial and Implementation: Implementing Hyundai SC-420MC Welding Wire

The feedback from the workshop floor was overwhelmingly positive. Workers found the new wire met and exceeded their expectations, highlighting its smoother operation and superior performance in positional welding. With his eye always on compliance, Martin confirmed that the wire satisfactorily met all necessary structural and safety classifications, further cementing its place within the company’s operations.

Results and Benefits: Achieving Excellence with Hyundai SC-420MC Wire

The transition to the new wire was surprisingly smooth, requiring minimal adjustments to existing procedures. Reflecting on the process, Wayne Martin noted, "Once again, as a welding supervisor, now do we need to change all our procedures... it was a lot less work for us, and it made for a smoother transition." This ease of integration and the wire’s compatibility with CO2 and a CO2-argon mix provided the flexibility Trinder Engineers needed to maintain productivity without sacrificing quality. Additionally, the new wire presented an unexpected benefit: it produced fewer fumes than the previously used "low fume" wires, addressing health and safety concerns more effectively and contributing to a safer working environment.

Reflecting on the transition, Martin noted, “I haven’t had one of my guys say to me that they didn’t think it was any good or was harder to use... it seems to run a lot smoother.” This endorsement from the team shows the wire’s positive impact on the company’s welding practices. The switch led to cost savings and enhanced productivity and safety, demonstrating Trinder Engineers' commitment to continuous improvement.

In conclusion, successfully adopting Proline Industrial’s Hyundai SC-420MC welding wire at Trinder Engineers exemplifies the company's proactive approach to overcoming industry challenges. By prioritising efficiency, safety, and compliance, Trinder Engineers continues to lead the way in the welding industry, setting a benchmark for others to follow. The insights gained from this transition, particularly the emphasis on cost-effectiveness without compromising quality and reduced health risks through decreased fume production, show the broader implications of welding wire selection. Through this strategic decision to adopt the Hyundai SC-420MC welding wire, Trinder Engineers boosts its operational efficiency in the welding sector and reflects the company's dedication to reducing environmental impact and promoting healthier work environments.

Watch the interview here: